For a decade or more, the larger broadcast ownership entities have been moving towards a consolidated, regional approach to managing their IT systems. Concerns for security, cost and staffing have driven this evolution.

The results have been mixed, in part because there is little uniformity from market unit to market unit in broadcasting, especially radio. Metaphors like “herding cats” come to mind when describing the problem.

Standardization works best for enterprises that can equip their front-line units identically because the business model is largely the same everywhere. Still, consolidated IT has contributed to keeping order across far-flung IP networks and bring-your-own-device employee environments.

Unfortunately, this model couldn’t be further from reality on the content development and delivery side. Radio’s configuration varies by day and daypart. While some dayparts are under IP automation control allowing for standardization, most markets of size air some live content.

This requires studios, microphones, consoles and the like — typically bespoke. The delivery of content to consumers relies on high-powered transmitters and complex antenna systems generally far from the studio and usually no-two-alike.

Add to this the “STL” content delivery mechanism, managing compliance with an array of laws, safety, the care and feeding of often very geriatric systems and other taken-for-granted challenges.

[Sign Up for Radio World’s SmartBrief Newsletter]

These days, finding technical staff with sufficient expertise in analog and information technology, as well as willing to adopt the 24×7 availability required to keep the revenue stream alive, has proven difficult. The generation of engineers who grew up in this environment is retiring. That light broadcast managers see down the tunnel is the headlight of a locomotive.

This makes the NOC model a significant challenge for radio’s front-line operations. No-two-alike environments and centralized management are mutually exclusive concepts. Trying to suss out the state of affairs at some mostly unfamiliar transmitter site hundreds of miles away based on the simple telemetry provided by even the best broadcast remote controls is a fool’s errand. Often the only additional knowledge is a frightened local employee dispatched to the transmitter as “eyes.” And dispatch requires precious time.

I think I may have stumbled onto the solution.

Outside the box

For several years I have been installing cheap, power-over-ethernet (PoE) IP cameras all over the place. Via assorted data paths, I can access these cameras from anywhere and put eyes on the systems I maintain almost as though I was standing there.

The architecture is simple. Usually I repurpose a retired PC from the office environment and load it with camera management software. Then I buy a power-over-ethernet switch on eBay or grab one my IT department has retired.

I configure the combination and add remote console access software like Logmein or Dualmon. The corporate IT department prefers that these facilities be air-gapped from their networks, so in most cases they live on an isolated cellular 4G hotspot network segment. Maybe Starlink if it’s available.

Just mount your remote eyes where they can see what’s important and wire them. I even have cameras in and outside tower doghouses, connected using short data links with hardware from outfits like Ubiquity.

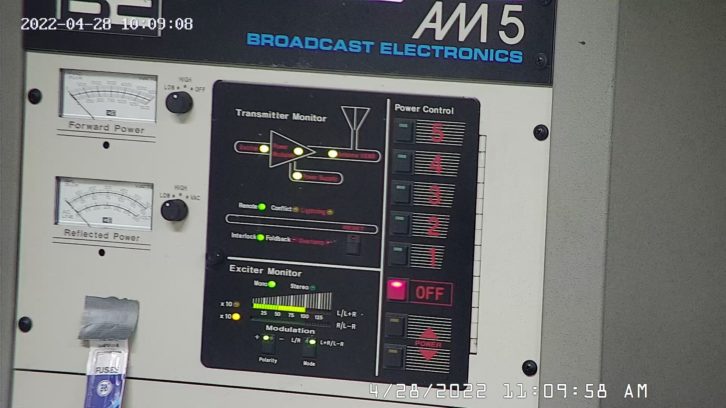

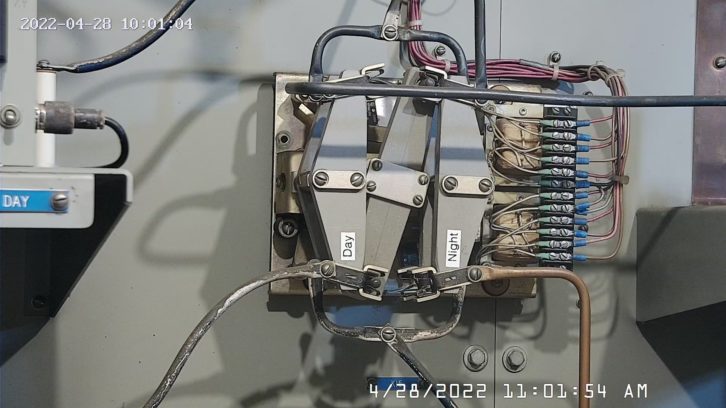

This facility allows me to remotely view nearly every device in the plant. I have saved presets for pan, tilt, zoom and focus for every panel and every indicator that might be useful in addressing a problem. As I interpret the telemetry from the remote control, I can confirm actions I take with real-time video of the result.

Parameters that might be overlooked because of limitations on the number of remote control channels now become accessible. Sometimes parameters don’t lend themselves easy remote measurement. Fuel levels come to mind, where designing an electrical interface with flammable liquids or gasses might be iffy. And there are countless legacy devices designed presuming the user would be on site. Modulation monitors are an example. Finally, pulling back for a wide shot of a familiar rack can help quickly determine the location of an interruption.

The solution

More importantly, this can be done from pretty much anywhere on earth.

This is how I believe the staffing dilemma that radio now faces can be solved or at least can be mitigated to a degree. The solution might take several forms.

Perhaps the most obvious is a centralized corporate NOC. Each radio station or other entity under remote management would document the program delivery flowchart in a few binder pages with photos showing the key components. Then the staff at the NOC could be taken on a video tour of the facility for familiarization, all without leaving their desks. This might be repeated on some pre-determined interval, so NOC personnel remain fresh on plant details including concerns and weaknesses.

Groups might create engineer teams, perhaps by time zone, where each local engineer on the team has familiarity with every plant in the region. There are any number of variations on this coverage theme. But underlying this strategy is familiarity with most common broadcast devices. Even devices that aren’t familiar are usually easier to understand if you can see them. No longer dependent upon someone else’s eyes or an opaque remote control for understanding, the chances for success are greater.

Comment on this or any article. Email rweetech@gmail.com.