In February, fire destroyed Central Michigan University’s TV transmitter building near Atlanta, Mich. Among the stations that lost facilities was 100 kW WPHN(FM), licensed to Northern Christian Radio.

WPHN engineer Del Reynolds came up with the temporary transmitter building that you can see in the photo, perched on a trailer at the tower site.

What looks like an outhouse is in face a chicken coop! Memories of the Beverly Hillbillies may come to mind. But the inside is nice and clean. And cooling is important, even for a temporary solid-state transmitter. You can see the box fan in the second photo, and the third image shows a vent that Del added to the chicken coop.

WPHN currently operates with engineering special temporary authority using a Nautel transmitter putting out 2.5 kW to achieve an ERP of 10 kW.

The photo is courtesy of Ed Trombley at consulting firm Munn-Reese in Coldwater, Mich. It’s a reminder that engineering consultants come across a lot of strange things.

Munn-Reese also publishes an occasional newsletter with topics of interest to broadcast engineers. You can find past issues at www.munn-reese.com.

Clip and save

Don Elliot’s “emergency” battery tester that we described in the May 8 issue brought a number of positive reader comments.

One engineer wanted to know the type of wire used. You’ll recall that it was very rigid to withstand rolling around in a tool bag while maintaining its form. It turns out that Don used a paper clip!

Simple is usually best.

That’s bull

We’ve shared mnemonics for remembering the resistor color code.

Bill Traue, principal of Bill Traue Technical Service LLC, was taught another by an early mentor who had served in the Navy: “Brown Bulls Raised On Young Grass Bring Very Good Wages.”

Simple tools

Returning to another recent topic, Paul Sagi reminds us that in a three-phase Wye system, if the phase currents are not balanced (equal) in each leg, there is current in the neutral. A neutral can overheat if the imbalance is too severe.

Measuring between phases, a good rule of thumb is for each phase to be within +5A of each other. By keeping the legs balanced, hot spots are eliminated, as all poles on the breaker or contactor heat evenly.

And continuing our discussion of tools to keep at hand: Paul says he carries a small mirror and tweezers in his toolbox, an old machinist’s habit.

He recalls a time when the air conditioner on his mother’s car stopped working. Her mechanic traced the problem to the air conditioning clutch, would cost $300 to repair.

Using his small inspection mirror, Paul located the contacts on the back of the clutch coil. After removing the silicone RTV, Paul used a little solder to re-flow the connections. Continuity was restored and $300 was saved.

Every day we use our skills to troubleshoot problems in broadcast gear. How great does it feel when we can apply those skills and avoid a costly repair bill?

Paul paints a humorous description of himself juggling mirror, solder, soldering iron and flashlight all at once to do the repair. The funniest part was that the mirror reversed directions; when he moved the soldering iron to the left, the image moved right.

Over the last couple of months, we’ve covered almost everything imaginable when it comes to important things to keep in our toolbags and toolboxes — but we haven’t mentioned these two.

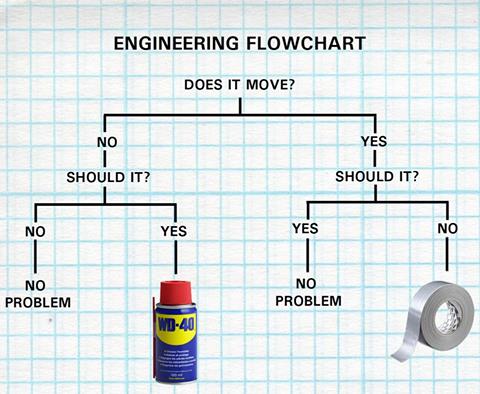

Jim Davies at the University of Iowa shares this troubleshooting chart that has made the rounds on the internet. What would we do without them?

Don’t be chicken! Grab your keyboard and peck out a Workbench tip! Email johnpbisset@gmail.com.