John Allan is vice president of marketing for CPI-Eimac Division; he read our series of comments about rebuilt tubes. John points out that the CCA transmitter uses a grounded grid triode, most likely the 3CX15000A7. For some reason, Eimac receives the most feedback about rebuilds of that particular type not working well for broadcasters.

By comparison, the industrial folks using low-mu triode oscillators seem to have the most success with rebuilds. Broadcast tetrodes seem to be more forgiving than the high-mu triodes, and Eimac gets both good and bad reports on those.

Proper alignment of both grids seems to be the critical element; it seems to vary from one rebuilder to the next – sometimes from one rebuilt tube to the next. It is Eimac’s position that when you need the lowest distortion and best match, a new tube is the way to go.

Obtaining the longest life from a high-power tube – whether a triode or tetrode – can only be achieved when you have a full understanding of the tube’s operation. With that in mind, Eimac publishes “The Care and Feeding of Power Grid Tubes,” now in its fifth edition. Single copies are available through Richardson Electronics. You can request a free copy by going to Richardson’s Web site: www.rell.com/litrequest.asp

John Allan can be reached at john.allan@cpii.com.

. . .

George Badger is a consultant with Econco after spending a career at Eimac. By far, the 4CX15000A is the most popular rebuild for broadcasters. George says Econco has developed several characteristic grades for this tube, and certain grades work better with one transmitter than another. All of these “grades” fall within the specs for the tube.

George’s point is that you should specify the transmitter you’re using when you buy a rebuilt tetrode tube from Econco. Triodes aren’t so much an issue. Econco tests each tube after rebuilding, and these tests define the operating characteristics, which can then be graded for certain transmitters. Econco knows the best characteristics for a Collins 819, for example, and will select one of those tubes from its rebuilt stock.

George further explained that the filaments used in these tetrodes are thoriated tungsten, not steel. A part of the rebuilding process is to inspect the filament and re-carborize it if needed. This process adds a layer of carbon to the filament. The depth of penetration of the process will determine how long the tube will last. If the carborization is not deep enough, the tube life will be shortened.

Why not just load on a thick layer? An overly thick layer of carbon will make the filament so fragile that transporting it by surface or airfreight will ensure its destruction. The tube will fail before it’s even used.

. . .

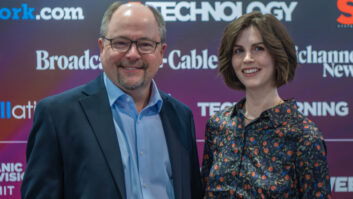

(click thumbnail)Fig. 1 Doug Hall and the first of seven edit suites at The College of New Jersey.

Doug Hall works with General Manager Kevin Potucek at the Communications Studies Department of the College of New Jersey. Fig. 1 shows Doug at the first of seven edit suites he and Kevin are installing.

The suites use Pro Tools, Final Cut and a Digi-002 console. An Avid package is to be added to the cassette, DAT and MD machines in each suite to provide state-of-the-art audio and video editing.

I often hear engineers lament, “Where will the next generation of engineers come from?” Schools like the College of New Jersey are stepping up with the answer. This is no “hand-me-down” studio; graduates will be trained on what’s current in the industry.

. . .

Joe Stack at Modulation Sciences writes, “I’ve discovered that sometimes a small burst of dry air is needed and there’s no can of ‘commercial’ dry air available. Using an empty plastic dishwashing soap bottle like Dawn or Joy, with the nozzle still on, will give a nice, forceful burst of air every time the bottle is squeezed, and all without batteries.”

Using this air bottle along with a small clean paintbrush can help push dirt from hard-to-reach places inside a transmitter or computer.

Have you wondered what to do with those little silica gel packs packed with products to absorb moisture? If you are worried about the air inside the bottle collecting moisture, Joe says, unscrew the cap of the plastic bottle and insert a little gel pack to “soak” up any moisture that might get in.

Sometimes, simple tips are the best.

Joe Stack can be reached at jstack@ieee.org

. . .

(click thumbnail)Fig. 2 Avoid the fine and repair damaged tower fencing quickly.

If you’ve monitored the trades, you’ve seen a number of stations fined for missing, inadequate or damaged tower fencing. Fencing seems to be a hot button for inspectors these days (along with EAS) .

The best course of action when this kind of problem is discovered is to show prompt diligence in getting it corrected, as the engineer did for the site in Fig. 2.

In another case, a station recently was fined for not fencing its tower, which was in a swamp. The station staff had figured that no one could get to the tower because of the swamp, so it didn’t need a fence. The FCC didn’t buy that.

Save yourself the fine and expense of fixing the problem. Some fencing contractors will barter with radio stations. But barter or not, don’t ignore this kind of problem.

. . .

We’re beyond most of the FM ducting problems by this time of year; but Dielectric’s Radio Product Line Manager Matt Leland passed on a Web site that you should bookmark for next year.

Ducting can drive an engineer crazy. Not only for FM reception, but RPU shots, too. Too many PDs and GMs attribute this phenomenon to “something” we engineers are doing wrong or not doing. “I can’t hear the station! It’s got to be the engineer’s fault!”

(I do remember one chief who used the phenomenon to get a spare set of new tubes. When you can’t hear the station, I guess management will do almost anything. I never sold a new transmitter as a result of ducting, but I guess it’s possible.)

This site will be helpful next year when Mother Nature starts tormenting us: http://home.cogeco.ca/~dxinfo/tropo.html

Matt Leland can be reached at matt.leland@dielectric.spx.com

Submissions for this column are encouraged, and qualify for SBE recertification credit.