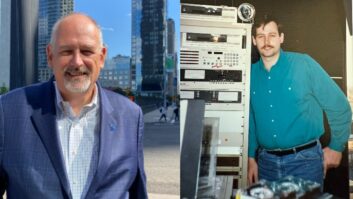

Fig. 1: The Presence app from People Power turns an iOS-based device into a WiFi or cellular-connected video camera. Bill Betlej handles all things communications and IT at Mary Baldwin College in Staunton, Va., and has contract engineering experience. He ran across a free app that you might enjoy.

The app lets you repurpose an old iPhone into a motion-detected security camera. It is called Presence and is produced by People Power, a Palo Alto software developer. Using WiFi, a second Apple device (like iPhone or iPad) can be used as a monitor. Presence can be programmed to record a five-second video clip when motion is detected, and send an email alert. Furthermore, you can set an unlimited number of Apple devices for motion detection.

The company recommends connecting devices to wall chargers so that they don’t run out of power and stop streaming. Using old devices as plugged-in security cameras won’t run up electric bills; at most, you can expect to pay an extra dollar if you use your devices this way for an entire year.

Even though the app is free, the company hopes users will go to the app’s Store and purchase accessories such as device tripods and fish-eye lenses to enhance security systems.

Presence is available from the Apple App Store; an Android version is expected by the end of the year.

Repurposing equipment is a favorite subject of this column, so thanks, Bill, for sharing.

* * *

The folks at phasor manufacturer and communications company LBA Group are offering training in OSHA liability, a topic that has largely been ignored by broadcast management. There are important new chemical safety training rules; and few employers realize their establishments fall under these new standards.

Even the use of benign chemicals, such as cleaning supplies, requires that companies provide workers with OSHA HazCom GHS training. OSHA mandates that all affected workers are to be trained to read and understand new safety data sheets and chemical labeling before Dec. 1 of this year or face major penalties.

To help you meet the deadline, LBA University offers comprehensive, online GHS training. In groups of five or more, the training costs less than $40 each. For information, contact Bryan Dixon at LBA, (252) 757-0279, or visit www.lbagroup.com/.

You can learn more about the requirement at www.osha.gov/dsg/hazcom.

* * *

Fig. 2: An example of Cortec’s corrosion protection products. In our column, many readers, including Southern California engineer Marc Mann have mentioned the use of silica gel to slow the effects of moisture formation on tools. Wrapping tools in a cloth after dousing with WD-40 lubricant only goes so far. And what about corrosion effects on electronic equipment?

In a publication of industrial products, Marc read about a company that produces tablets that protect metals inside packages; it uses a technology that releases a “vapor phase corrosion inhibitor.” Marc thought this would be great but that what we really need is a product that can be placed inside of cabinets and housings that could provide this same protection to electrical and electronic equipment.

He called the firm, Cortec Corp., and spoke with Robert Kean. Marc asked if their product would work inside of operating, powered-up devices.

As it happens, Cortec manufactures a range of products that utilize this technology to protect valuable electronics from corrosion. Best of all, they do not need to be in a sealed bag. The “emitters” range from label-sized, self-adhesive-backed types to containers with breathable membranes to allow the area of choice to be protected.

They are non-toxic and safe to handle. They can be placed in just about anything from fuse boxes to telecommunications equipment — even inside of microphones. Marc foresees these being used in not only the transmitter plant but in remote equipment that will be exposed to moisture and high humidity.

If you’re plagued with corrosion, this might just be the answer. Marc ventures to say a station engineer might never run out of places this product could be used, including tool boxes.

Robert Kean can be reached at Cortec Corp. at (800) 426-7832. The website is www.cortecvci.com.

Engineers have been fighting corrosion for years, especially near large bodies of water. Having a product that can be placed inside the equipment to be protected is wonderful news.

* * *

Paul Sagi often has neat thoughts about topics we discuss in Workbench. Remember our parabolic microphone project, using a discarded satellite dish, for adding audio realism to high school sports events? Positioning a microphone on a parabolic dish, Paul noticed that the dish was shiny; so he pointed it towards a light and positioned the microphone so there was a bright spot of light on the end of the microphone element. He did this in a darkened room, pointing the dish towards light from another room.

It’s a quick way to align the mike to the focal point of the dish.

Paul used a similar idea to position stereo speakers. Put a small mirror on each speaker. Now darken the room. Go to the listening position and shine a flashlight, looking for a reflection from both mirrors at the same time. Reposition the speakers as required.

Thanks Paul!

Contribute to Workbench. You’ll help your fellow engineers and qualify for SBE recertification credit. Send Workbench tips to johnpbisset@gmail.com. Fax to (603) 472-4944.

Author John Bisset has spent 44 years in the broadcasting industry and is still learning. He is SBE Certified and is a past recipient of the SBE’s Educator of the Year Award.